Roller Gear Cam Mechanism

In this mechanism, cam followers mounted to a turret is always in the state of regulation by the grooves in the periphery of a cylindrical cam or rib when the input shaft rotates 1 rotation 360 degrees, and the movement of the cam followers are controlled by the form of the cam grooves or the rib. The index is led by a lead part equal to the cam index angle, and complete moving to the next station. In addition, the dwell regulates it in the way of sandwiching a straight rib from the outside.

Roller Gear Cam Handling

Cam handling is to decide on the rotational direction of the output shaft, and there are 2 types, right handling cam (R) and left handling cam (L) on the following figure. It suggests the direction of the index rollers against the rotation of the main cam shaft (input shaft).

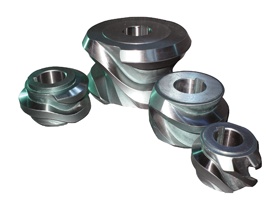

Cams for Indexers

Single Dwell Cam & Twin Dwell Cam

MYDEX roller gear cam has single dwell cams for low, medium speed and light, medium duty, and twin dwell cams for high speed and heavy duty as a standard.

In the single and the twin dwell cams, the angle of cam followers that sandwiches the cam ribs when dwell time (Retaining angle) is different. Twin dwell cams have advantages in high speed in terms of residual vibration problem, etc with output shaft rigidity when dwelling time or after index time owing to a large retaining angle. In single dwell cams, when shifting the speed-up point into

down (inflexion point: the yellow part on the diagram), The phenominan that the rotational direction of the cam followers reversed can be seen, in parallel, between cam faces and cam follower onter rings are not rolling friction, but instant sliding friction occurs.

Twin dwell cam is that the cam followers sandwich cam ribs and rotate the same direction all the time in which sliding friction does not occur. Therefore, twin dwell cam is advantageous agaist wear at high-speed operation and extremely effective on residual vibration. We reccomend twin dwell cam if the operating revolution is more than 200rpm.

Cam Types

Indexer cams have cam type 1 and 2. Cam type 1 has a move and a stop once each in 360°of cam periphery. Cam type 2 has a move and a stop once each of single and twin dwell in 360°of cam periphery. The standard specifications have a move and a stop once each in 180°and mainly used for supporting malti-index (large number of stops). Also, compared to cam type 1 at the same specifications, the torque transmission is higher because large rollers can be placed.

Cams for Oscillators

Oscillator cam is designed for reciprocating motion of output shaft, and after swinging at an optional angle to a certain direction, the cams are retured back to the original position led by grooves of return direction of the cam rib. The motion property is excellent as indexer cams.